Reducing Costs and Downtime in Oil and Gas with Drones

UAE's oil and gas industry is changing pretty fast by

adopting various technologies that enforce all measures of safety, operational

cost reduction, and downtime minimisation during exploration, production, as

well as pipeline management.

Probably the most discussed innovation over the last few

years would be the use of drones to change how critical infrastructure looks

during monitoring and maintenance.

By providing safe, data-driven insights without

requiring any dangerous manual inspection, drones are changing operations,

starting from offshore rigs straight down to pipelines in the middle of the

desert.

In the course of development of these technologies, they

are becoming essential in daily operations in the energy sector. Let us see

more about the technology and how a drone company can revolutionise the

inspections effectively.

Causes for Quick

Smart Inspection Methodologies in Oil and Gas

Oil and gas assets extend across the UAE coastal areas

into very deep deserts. Traditionally, entire infrastructures were

manpower-powered to inspect, and often also needed very complicated logistical

efforts and long shutdown periods.

Scaffolding, helicopters, rope access, or ground-based

teams working under conditions that (by default) are extremely hazardous had

all been the usual mode of operations for such inspection works.

Very slow, expensive, and dangerous system at the

moment. All these derived continual efforts by companies to come up with safer

and better alternatives to minimise exposure to risks and maximise speed, as

well as accuracy in inspections.

Drones are for oil-and-gas inspections in the UAE

because they have transformed how companies do their inspections through

drones, with the main goal of fast inspections without stopping the operation

of heavy machinery in the places where they are installed.

Emerging Challenges in Oil and Gas Inspection

Operations in the industry go on, most of which relate

directly to the maintenance and inspection works. Such problems include:

1. High Operational

Costs

Manual inspection necessitates spending a high amount

for specialised staff and independent support equipment; their costs are mostly

combined as

2. Downtime Not to

Purposes

Financial losses incurred during shutdown due to faults

or scheduled maintenance.

3. Safety and Health

Risks at the Workplace

Every inspection involves risks as it includes areas at

heights, confined areas, and flammable materials.

4. Lack of

Visibility

Traditional systems do not always allow for capturing

accurate information for strategic decision-making or timely value. New

technologies would generate value without putting additional risk or expenses

in place, so an inspection with drones could offer that.

How Aerial

Technology Cuts Down Costs

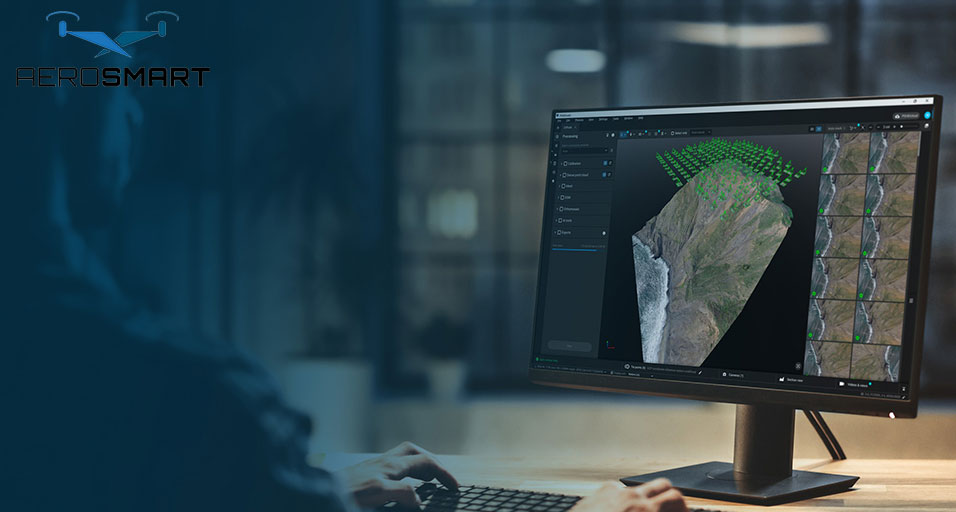

New drone technology avails during inspection and

maintenance procedures cost advantages at every stage. The companies save money

by avoiding the erection of scaffolding, the flying of helicopters, or the long

periods of operation shutdowns. Drones with thermal cameras, lidar, or

high-resolution sensors will give remote, clear, and precise information in

just a couple of minutes.

The custom inspection service provider also saves an

absorbed amount of personnel that would otherwise be spent on less important

decisions instead of being at the locus in the field. Any popular drone company

provides equipment which can cover large areas fast, hence eliminating a

large portion of total inspection time.

Minimising Downtime

through Real-Time Insights

One of the major advantages of drone inspections is the

possible early indications of potential problems, which allow for unplanned

downtimes to be prevented. Operators can take immediate action in real-time

from corrosion or leaks detected to structural damage or blockages.

These rapid actions render much more reliable systems

and efficiency on the overall front. Moreover, a fast inspection means more

time to schedule maintenance during shutdowns, all ultimately culminating in

improved operational efficiency.

That is why drones for oil and gas inspection UAE are

rapidly becoming a significant component in integrated workflows across the

Emirates.

Remote Control at

Work

The worker is manually monitored in terms of exposure,

under an offshore, above-ground tank, and high-pressure pipelines, to secure

operations. By merging with advanced long-distance excellent visual and thermal

data, drones can now replace the physical requirements of accessing these

hazardous regions of airspace, above-ground storage tanks, and very

high-temperature pipelines.

● The most dangerous assignments

are entrusted to the drones.

● Fewer accidents on site.

● Minimal usage of risky equipment

like ladders or ropes.

Accuracy of Data and

High Quality Images

The quality and accuracy of data are unpredictable. Data

integrity comes first, toward decisions that are worth oil and gas. In this

regard, drone systems stand shoulder to shoulder with above-ground inspection

because of their performance in clearer results, a great deal of detail with

respect to their outputs, when advanced imaging technology has been used on the

data collection process.

Maintenance teams have become increasingly competent in

recognising problems and prioritising repair work required for immediate

attention. All of this amounts to high-resolution imagery, thermography, 3D

mapping, and installation of methane detection sensors, which are generating

broad visibility into the asset conditions.

The indications from these are that organisations have

taken a proactive approach rather than a reactive one toward unplanned failure.

Uses of Drone

Technology in Oil and Gas Applications

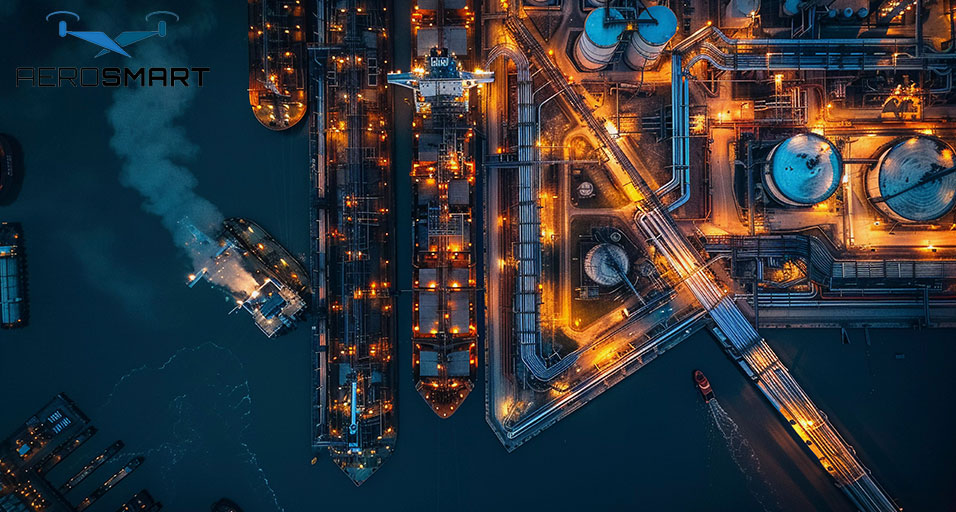

Several oil and gas activities fall within the scope of

usage of drones for oil and gas inspection UAE. The pipelines are traditionally

the most cited applications:

1. Flare Stack

Inspection

Shutdown is unnecessary since active flare stacks can

approach drones whenever necessary for measuring. Internal tanks have their

inspections designed by specially designed confined-space platforms using

drones.

2. Partial Offshore

Rig Surveys

Corrosion and structural problems can be identified as

safety hazards in marine environments. Possible air and methane leakages and

the impact of changes on surrounding ecosystems are monitored.

Future Plans on the

Advancements in Drone Technology

Innovations in the UAE have always extended their

significance into the domain of technology in the industry. It is at such times

that companies find themselves under increased pressure to ensure improvements

in line with the significant oil and gas expansions across Abu Dhabi, Fujairah,

and offshore areas.

The most cited characteristic of

rapidly growing acceptance for using drones is:

● Safe and sustainable

environmental inspection methods

● Part of very ambitious national

digital transformation initiatives

● Bigger needs for predictive

maintenance

● Rapid-response tools needed in

emergencies

● The otherwise sparse, mostly

desert, vast stretches and offshore

Early drone technology has already made it possible for

the firm to enjoy savings in operational costs and future costs, too.

What is next in

Drones in Oil and Gas?

Basic industrial revolution will always accompany new

developments; the features mentioned above will ensure that there will be

further sophistication and streamlining of drones:

● Distance Long totally autonomous

flying

● Predict damages using AI

● Integration as part of pipeline

communications into digital twins

● Methane and gas detection will

be enhanced

It will transform inspections concerning efficiency,

cost reduction, and better regulatory compliance.

Conclusion

At present, therefore, drone technology is no longer

something experimental in oil and gas operations in the UAE, but rather part

and parcel of practical life.

From saving on inspection time, inspection costs, of

course, safety, and unmatched data precision, which is part and parcel of the

region's commitment to innovation and sustainability, businesses will see

measurable improvement in efficiency once drone-based inspections are

integrated into maintenance strategies.

This kind of technology integration also means increased

uptime while enhancing worker safety. Further into the industry's growth,

aerial technology continues to promise as the latest way to achieve excellence

in asset management and operations.